3d Lamination Glue

3d laminating whether your application requires a simple approach such as using a vacuum press or a more complex process like that of a membrane press black bros.

3d lamination glue. Sheet lamination is one of the seven recognized 3d printing methods. 3d lamination is applied at a high temperature and high vacuum pressure to perfectly bond the laminate to the wood core at the molecular level. We will help you choose the optimal 3d foils and adhesives and are also able to consider your individual requests. Types of glue for laminating.

We tested products from west max general purpose the epoxy store gorilla three bond git rot and others. We sampled a few different glues advertised for rv s and concluded that there is no comparison to the composet slv formula. The term laminating can apply to three different procedures. Low static adhesive rollers and or compressed air.

Many new developments in adhesive technology and in the 3d laminate product have helped move the manufacturing of 3d laminated parts into a more viable approach for a wider variety of wood product manufacturers. 3d hot lamination requires careful treatment of the workpieces both before and after as well as a high level of expert knowledge. A brief look at the different lamination and adhesive methods and applications. Take any quality 3dl supplier and look at the depth of design color pattern and texture that is being introduced to the surface.

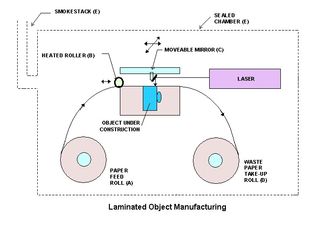

The first is the one woodworkers use to glue together planks of wood to form a wide surface for a. The conventional process for manufacturing a table top so called high pressure lamination or hpl involves gluing down a thin sheet of laminate to the top of an mdf particle board panel. The process is also called ultrasonic additive manufacturing uam in case the building material used. The process uses sheets of building material which are cut through laser or knife and the sheets are joined one after the other either by using an adhesive or by wielding the laser cut sheets together to form the 3d object.

Can provide the high quality equipment to get you there. Therefore the adhesive crosslinker ratio can be adapted individually to the materials to be laminated as well as to the requirements for the bond. Pud polyurethane dispersion is a water.