4 Layer Laminate Package Ic

Laminate is constructed in layers to create lasting affordable beautiful floors.

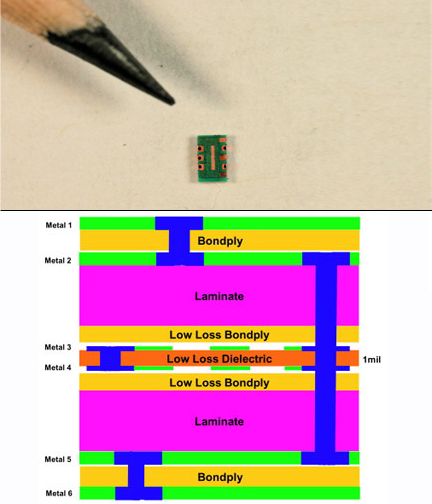

4 layer laminate package ic. No matter how hard you push on it when you mount it to the package those bumps aren t going to dig down through the laminate layers of the package. The pad pitch is 120μm with an 80μm pad size. There are a variety of ways to categorize ic packages based on formation. Some package types have standardized dimensions and tolerances and are registered with trade industry associations such as jedec and pro electron.

The line space specs are 10μm and above. Design flows are not able to address multiple technology designs ic laminate package and pcb need to be designed together em interactions between substrates need to be modeled and accounted for the need to move from disjointed tools design flows to. Additionally a category for wafer ic assembly known as wafer level packaging wlp has caught on in industry parlance. As such there are two types of ic packages.

Four reasons to avoid multi layer flip chip pin padstacks. The lead frame type and the substrate type. Multi technology examples 2. Illustrate with few applications single chip module multi chip module flip chip solder bumps module transceiver module electro thermal simulation 5.

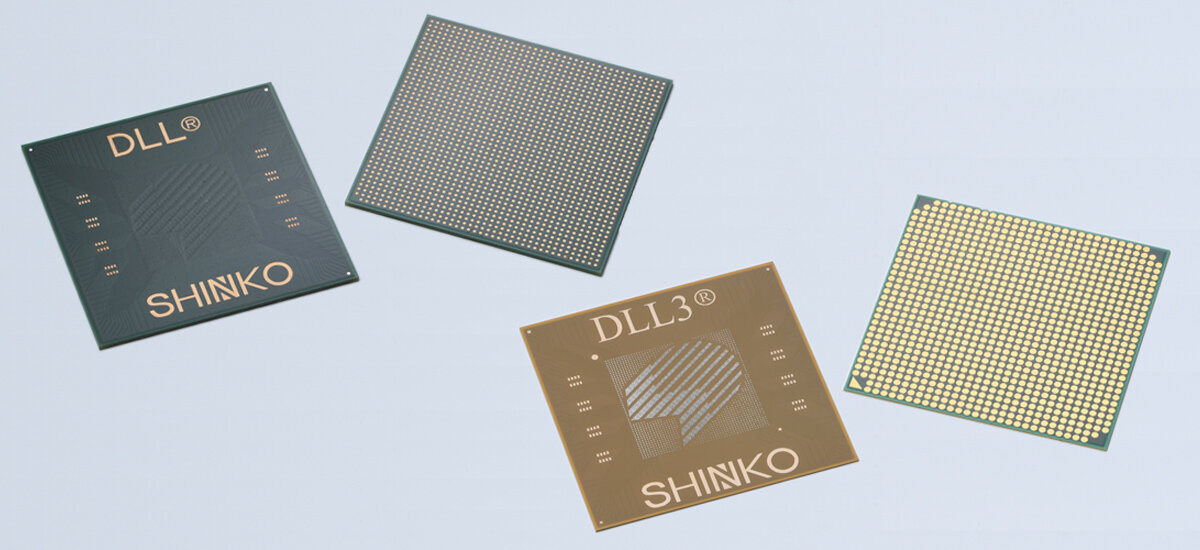

A very large number of different types of package exist. Improve electrical performance and incorporate higher ic functionality amkor flip chip bga fcbga packages are assembled around state of the art single unit laminate or ceramic substrates. The pins can be placed on top of vias which connect to objects on other layers but the pins themselves cannot do so. Four layers of material each of which has its own purpose are fused together through a direct pressure process that binds them into one extremely durable material.

Ic laminate package multi technology pa module design agenda 1. Utilizing multiple high density routing layers laser drilled blind buried and stacked vias and ultra fine line space metallization fcbga. These laminates feature superior versatility and come with excellent properties that make these suitable for wide variety of packaging applications. Semiconductor device fabrication is the process used to manufacture semiconductor devices typically the metal oxide semiconductor mos devices used in the integrated circuit ic chips that are present in everyday electrical and electronic devices.

Ic laminate package multi technology module design challenges. It is a multiple step sequence of photolithographic and chemical processing steps such as surface passivation thermal oxidation planar. Improved design methodology 4. In sesub the most common configuration is an embedded package in a 4 layer substrate but some are developing 2 5 and 6 layer options.